Step up to combine harvester specialist status.

With the market launch of their mower-thresher-binder machine, the CLAAS combine harvester pioneers of the 1930s and 1940s – Professor Karl Vormfelde, Dr. Walter Brenner and August Claas – had opened the door to the combined reaping and threshing process in Europe. After selling almost 1,400 machines, they knew that the combine harvester had become an integral part of the agricultural landscape. To maintain the lead which they had built up over the rest of the market, the Class brothers channelled all the company’s resources into combine harvester production. In 1968, they celebrated the production of their 200,000th machine. This meant that CLAAS had become one of the world’s leading combine harvester producers.

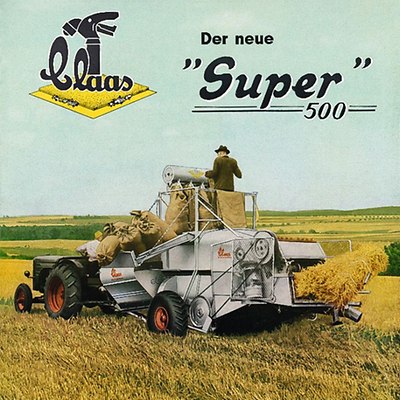

Shining silver at the Harsewinkel company complex in 1948. The SUPER combine harvester rolled off the production line in large numbers. A total of more than 65,000 of this family of combine harvesters were made in the years from 1946 to 1978.

In summer 1946, representatives of the British government in London were visiting the Harsewinkel plant almost daily, examining the production plant and the semi-finished or finished machines on the plant site. In Britain, as in Germany, the farming sector had considerable ground to make up after the war in terms of technical progress. To address the pressing foot shortages back at home and in the occupied parts of Germany, they were even looking to the former enemy for answers – and found them in the CLAAS development department.

The people at CLAAS were deeply shocked when representatives of the British military administration confiscated one of their three SUPER combine harvesters – which had only just been developed – and shipped it off to England. They were worried that the new machine, which they were hoping would become the foundation for the firm’s future prosperity, might now be made instead by English manufacturers, as a form of war reparations. However, these fears proved unfounded.

All that happened was that an English testing body was commissioned by the British Ministry of Agriculture to test the machine in local harvesting conditions, and duly awarded the CLAAS combine harvester an excellent mark. The SUPER even outperformed its English and American counterparts. This success played a part in setting the firm up for a successful new beginning after the war since, finally, the firm was given permission to resume the production of its combine harvester. Raw materials were now becoming available again, and the plant began to receive consignments of vital inputs for its production operations: iron, tyres, coal and timber. The factory premises in Harsewinkel were expanded, and the offices in the development department gradually became a hive of activity as before.

The company shipped its first consignment of 13 combine harvesters to the British Isles already in 1976, to the “Mann & Son” firm, based in Saxham, in the grain farming region of East Anglia. The firm was a dealer in Lanz tractors, and now also planned to sell CLAAS combine harvesters. CLAAS shipped several hundred machines already in 1948 and 1949. The restart of the company’s operations after the war had now been successfully achieved.

Race for market leadership

The SF, the first self-propelled CLAAS combine harvester, had a cutting width of 2.40 metres. Right from the outset, it was optionally available with a grain tank, or, as seen here, also with a bagging platform.

Elsewhere in Europe, however, and particularly in Germany, the production of straw binders and stationary threshing machines continued to flourish in the post-war years, and into the 1950s. CLAAS was almost the only supplier of combine harvesters in Europe. There were two main reasons for this: first, not everyone was convinced of the merits of the new combined reaping and threshing process, and second, CLAAS well ahead of the competition, with almost 1,400 machines out in the field and development experience extending back to 1930. Competition took some time get started, but by the end of the 1950s, there were more than 30 combine harvester suppliers in Europe. This unleashed intense competition in the combine harvester market.

The team at Harsewinkel had long been making plans for this eventuality, however. Every morning, the three managing partners – the brothers August, Franz und Theo Claas – could be found sitting around the desk in the “office”, reading through the mail, along with the sales manager, Walter Voss and the plant manager, Alfons Siepenkort. This meeting performed a highly effective function as a daily briefing on the current situation of what was still a small family firm. Often, they would also meet when the day’s work was done to enjoy a glass of two of “Münsterländer Korn” (corn schnapps). A chat while relaxing with a cigar was the source of many of their best ideas, and the discussions would sometimes continue well into the evening.

It was at one of these sessions that they made the momentous decision to make holding the market leadership position in Europe their top priority. This was a highly ambitious goal for a relatively small firm, contending with some far larger international competitors. It soon emerged that their greatest challenge was going to be keeping up with the sharply increasing demand for combine harvesters, and maintaining prompt deliveries.

Staking everything on one card

In order to keep up with the competition, the firm would clearly have to boost its production capacity, and above all expand its distribution operation – no easy task for a family business with no external sources of capital. For this reason, the partners decided to focus all the company’s resources – staff, development, production and sales – on the combine harvester. Accordingly, the manufacture of other products, even the firm’s highly profitable baler business, with which the company had made its name in the early days, was drastically scaled back.

The firm’s first off-site plant – a foundry to supply the combine harvester plant in Harsewinkel with cast iron parts – was opened in 1948 in Gütersloh-Blankenhagen. Six years later, in November 1956, a third production operation was set up in Paderborn, to make the drive and hydraulics components for the firm’s combine harvesters. The partners were on the lookout for suitable production locations across the border in France. In 1953, August Claas purchased a construction site of approximately 9 hectares in St. Remy-Woippy near Metz in Lorraine. Here, in the heart of Europe, at the point where three countries meet (France, Germany and Luxembourg), he planned to set up a completely new baler production operation. The construction of the new baler plant was held up by protracted negotiations with SNCF, the national French railway operator, but production finally started in autumn 1961. In 1960, a further plant was set up in Schloss-Holte near Bielefeld, for the production of hydraulics components.

Beginning of a new era: a parade of the first self-propelled CLAAS combine harvesters, introduced from 1953.

Combine harvester advertising

This capacity expansion programme was accompanied by intensive efforts in the sales area to open up new markets for the combine harvester. At the end of 1950, August Claas and his son Helmut spent several weeks in South America (Uruguay, Argentina and Brazil), to look in detail at the opportunities for the use of CLAAS machines in the region, and to set up the commercial relationships required for an export operation. At one stage, consideration was even given to establishing a production location in Uruguay, but this idea was ultimately shelved.

The crucial requirement for boosting unit sales was to build up the firm’s distribution structures. The approach followed was to install “plant representatives” in the relevant markets, with the task of identifying suitable dealers and agents, and supporting their operations. Subsequently, CLAAS appointed a general importer for each country, as the entity responsible for both import and distribution. The firm generally maintained very close and friendly relationships with these representatives abroad.

Numerous marketing promotions were also undertaken. The most effective forms of marketing proved to be hands-on demonstrations in the field and agricultural machinery exhibitions. These were regularly organised in impressive fashion with the assistance of the Customer Service department and the foreign representative entities.

To ensure a professional standard of marketing and customer communication, a Press Relations and Advertising department was also set up as early as the mid-1950s. Its task was to run regular advertising campaigns in agricultural print media to increase the level of acceptance of the new combined reaping and threshing process. Advertising volumes rapidly increased, with half-page ads giving way to full-page formats, another area in which CLAAS was a pioneer in the agricultural machine industry. During the harvesting season, the firm featured in weekly publications every two weeks. Machine brochures also became more comprehensive, more colourful and more informative. Targeted mailouts and advertising films with high production values were also used in order to convince the many who still remained sceptical of the benefits of the combined harvesting process.

Rapid growth

The new production strategy, focused primarily on the combine harvester, paid off handsomely for the firm. Over the ensuing years, the firm regularly reported meteoric growth figures. The Claas brothers had started the business up again in 1945 after the war with just 127 employees. Just five years later, that number had soared to 660, a more-than-fivefold increase. In order to meet the production demand in subsequent years, the firm had to open the new manufacturing plants already mentioned, and also started to recruit high numbers of employees from abroad, particularly Spain.

At the high point of combine harvester production in 1965, there were more than 5,300 staff working for the Harsewinkel-based agricultural machinery producer. On average, combine harvester production had increased by 80 percent a year since 1945. This was reflected in sales revenue growth from approximately DM 12 million in 1949, to over DM 370 million in 1965.

As the technology became more widely used, within the space of a few years, the combined harvester became the leading product within the agricultural machinery industry in revenue terms. In 1961, the sales revenue of CLAAS plants, at DM 288 million, represented more than 50 percent of the total German combine harvester industry. In just two decades, CLAAS had therefore become one of the leading combine harvester and agricultural machinery producers, not just in Germany, but worldwide. What had begun as a small family firm in eastern Westphalia, with its patented knotter and straw binders, was now one of the established big players on the international agricultural equipment stage.

Chapter selection:

1913 – 1929: It all started with a knot

1930 – 1945: The combine harvester revolutionised harvesting

1946 – 1968: Transition to combine harvester specialist